(1) Speed limiter installation

① The speed limiter should be clean and free of oil stains, and the speed setting seal should be intact and free of any signs of disassembly.

For example, when inspecting a speed limiter on an elevator, the inspector should find each setting seal on the speed limiter according to the speed limiter type inspection certificate and the installation, maintenance and operating instructions, and observe that the seals are intact.

② The speed limiter should be marked with up and down arrows and text instructions in the same direction as the elevator's running direction.

③ After the speed limiter is installed, a linkage test should be carried out. After the car safety clamp is activated, the traction wire rope should slip on the traction sheave.

④ The verticality of the sheave flange end face relative to the horizontal plane should not be greater than 2/1000.

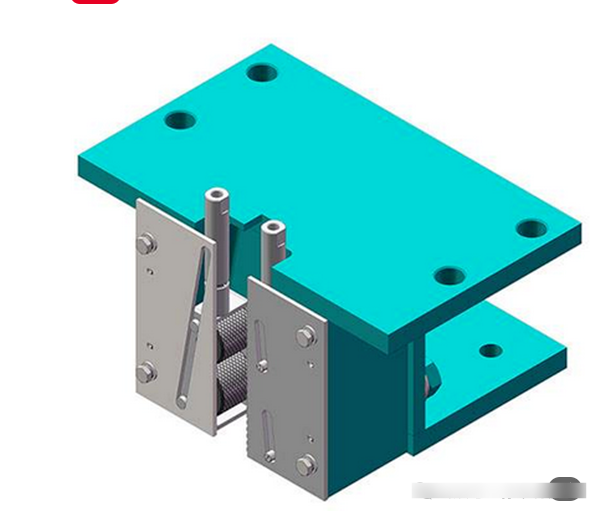

(2) Safety clamp installation

The setting seal of the safety clamp should be intact and free of any signs of disassembly. The gap between the safety clamp and the guide rail should meet the elevator design requirements. (3) Buffer installation

① The buffer should be free of rust, the oil circuit should be unobstructed, and the buffer oil should be filled as required by the instructions. The verticality of the hydraulic buffer plunger should not be greater than 0.5%.

② The deviation between the center of the buffer plate of the car and counterweight and the center of the buffer should not be greater than 20mm.

③ When multiple buffers are used at the bottom of the car or counterweight, the distance deviation between the top surface of each buffer and the car or counterweight should not be greater than 2mm. The buffer distance should be adjusted according to the design requirements of the elevator and the size should be marked on the shaft wall.

④ During the buffer action test, the time from the column being fully compressed to fully reset should not be greater than 120s. Before the buffer returns to its normal position, the electrical switch cannot be reset and the elevator cannot be started.

Elevator whole machine acceptance

(2) The speed limiter, safety clamp, buffer, and door lock device must be consistent with their type test certificates.

(3) The car (or counterweight) down sign on the speed limiter must be consistent with the actual down direction of the car (or counterweight). The rated speed and operating speed on the speed limiter nameplate must be consistent with the elevator being inspected. The speed limiter rope tensioning switch, hydraulic buffer reset switch, etc. must operate reliably. The speed limiter and safety clamp electrical switches must operate reliably during the linkage test and should cause the drive main unit to brake immediately.

(4) The upper and lower limit switches must be safety contacts and must operate normally during the operation test at the terminal position. They must operate before the car or counterweight contacts the buffer and remain in the operating state when the buffer is safely compressed. The upper and lower limit switches are the second layer of protection after the limit switch does not operate. Once operated, the main power supply will be cut off and it needs to be reset before it can be restarted. They are located at the top and bottom floors of the shaft and are generally installed at the guide rail end. The operating distance is 50 to 100 mm.

(5) For instantaneous safety clamps, the car should be loaded with an evenly distributed rated load; for progressive safety clamps, the car should be loaded with an evenly distributed 125% rated load.

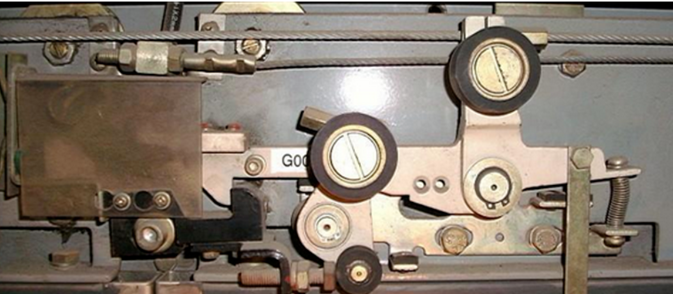

1. Elevator speed limiter.

This is a safety control component in the elevator safety protection system. If, for any reason, the elevator car exceeds speed during operation, or even poses a risk of falling, and all other safety protection devices are inoperative, the speed limiter and safety clamp will work in conjunction to stop the elevator car.

The elevator speed limiter constantly monitors and controls the car speed. When it exceeds 115% of the elevator's rated speed, it issues a signal, mechanically disconnecting the power supply circuit and braking the traction mechanism. If the elevator still fails to brake, the safety clamp installed at the bottom of the car activates to force the car to a stop. The speed limiter is the signal issuer, while the safety clamp is the executor. The combined action of these two factors gives rise to the concept of a safe elevator.

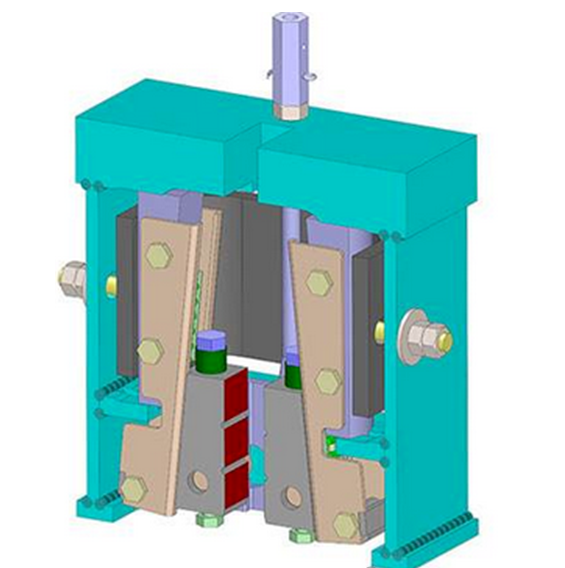

2. Safety Clamp.

The safety clamp is an elevator safety device. Under the control of the speed governor, the elevator car is brought to an emergency stop and clamped to the guide rails when the speed exceeds the speed limit set by the speed governor, or when the suspension rope breaks or slackens. It provides effective protection for the safe operation of the elevator and is generally installed on the car frame or counterweight frame. Safety clamps are categorized as one-way and two-way. However, due to the complex manufacturing process, two-way safety clamps are not yet widely used in China.

The operating principle of the safety clamp is as follows: the safety clamp lever drives the speed governor wire rope, and the tensioning pulley maintains friction between the speed governor wire rope and the speed governor pulley, ensuring that the speed of the speed governor pulley is consistent with the speed of the car.

When the car (safety clamp, safety clamp lever, speed governor wire rope, speed governor pulley) is running at or above 115% of the rated speed, the speed governor activates, and the brake rope block compresses the speed governor wire rope, stopping it and driving the safety clamp lever, causing the safety clamp to activate.

Safety clamps are divided into instantaneous safety clamps and progressive safety clamps. Instantaneous safety clamps are used for elevators with a speed of ≤0.63m/s, and progressive safety clamps are used for elevators with a speed of >0.63m/s.

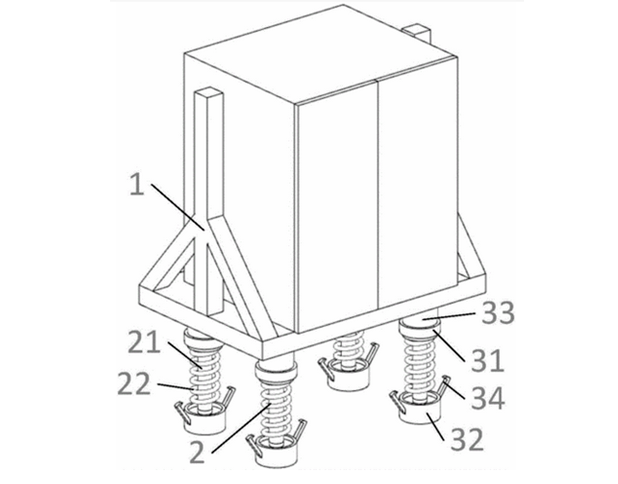

3. Buffers.

Buffers are the final component of the elevator safety system, providing cushioning in the event of an elevator malfunction or accident. This protects the elevator and its occupants from direct impact.

Elevator buffers are primarily categorized as hydraulic, spring, and polyurethane. Hydraulic buffers are widely used because they can accommodate a wide range of speeds and tonnages, while spring buffers are used in low-speed elevators.

4. Door lock.

The elevator door lock hook is a device that automatically closes. A spring on the door lock pushes the hook downward. This means it automatically closes without external force and keeps the elevator hall door closed. This function ensures the elevator door remains securely closed, preventing the door from being easily opened. Furthermore, once the elevator door lock is fully closed, the electrical switch on the door lock is turned on, allowing the elevator to operate normally.

[Tech-Blog]OX-088D Elevator Electronic Safety Gear Instructions

[Tech-Blog]OX-088D Elevator Electronic Safety Gear Instructions

[Company news]Cause analysis and treatment process of 6 typical elevator failure cases

[Company news]FUJI Precision Elevators at Nigeria Exhibition | VR Experience of Our Factory

·OX-088D Elevator Electronic Safety Gear Instructions

·OX-088D Elevator Electronic Safety Gear Instructions

·Cause analysis and treatment process of 6 typical elevator failure cases

·FUJI Precision Elevators at Nigeria Exhibition | VR Experience of Our Factory

·Elevator China | Why FUJI Precision Elevators Are Trusted Worldwide

·FUJI Precision Elevator in Nigeria Villa Project Nears Completion

·What should be inspected during routine elevator inspections? How should it be inspected?

Contact Us

×