本文介绍默纳克系统下的主机自学习方法

1、要做电机磁极定位,首先要确认下表中的 电机的铭牌参数。参数设置错误影响电机调谐无法实现优良的矢量控制。

保证主机抱闸能够完全打开的情况下操作以下步骤

Perform the following steps on the condition that the Main Controller brake is fully released.

同步主机自学习方法 Self-learning Method for Synchronous Main Controller

将电梯拨成检修状态。设置编码器的类型及脉冲

Fl-00=0、 Fl-12=2048、 Fl-25=1

Set the elevator to inspection mode. Configure the encoder type and pulse parameters.

Fl-00=0、 Fl-12=2048、 Fl-25=1

一、无负载调谐方法(主机未挂钢丝绳)

No-load Tuning Method (Main Controller without Steel Wire Ropes Attached

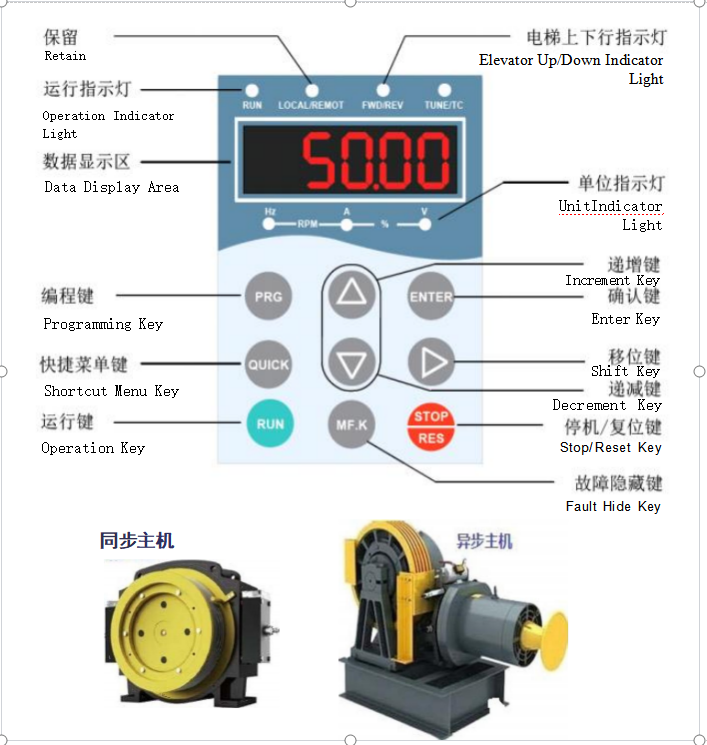

1) 设置好以上参数,设置F0-01=0按操作器上的复位键STOP清除故障 (小屏幕 不能显示E52和E51故障)。

Set the above parameters properly, set thevalue of F0-01 to 0, and press the reset button STOP on the operator to clear faults (the small screen must not display fault codes E52 and E51).

2) 设置Fl-ll=2。这时小屏幕上显示TUNE。

Set F1-11 to 2. At this point, "TUNE" will be displayed on the small screen.

3) 顶住抱闸接触器BY不放,按操作器的右下角的绿色的RUI按键,电机发出"哽" 的一声后,转动10秒左右自动停止, 电机自学习完成,松开抱闸接触器。

Press and hold the brake contactor BY without releasing it, then press the green RUN button at the bottom right corner of the operator. The motor will emit a "clunk" sound, rotate for about 10 seconds and then stop automatically. After the motor self-learning is completed, release the brake contactor.

4) 学成后,F1-06即是电机角度。至少按照以上步骤做三次电机学习,误差范围 应不超过5 ° ;学习完成后更改F0-01=l.

After completion of self-learning, the value of F1-06 is the motor angle. Perform the motor self-learning at least three times following the above steps, with the error range not exceeding 5° . After the self-learning is finished, change the value of F0-01 to 1.

5) 当相序不对时,报E20故障子码3。调换输出线的U,V两相,重新进行主机自学 习即可。

If the phase sequence is incorrect, fault code E20 with sub-code 3 will be reported. Swap the two output lines U and V, and perform the main controller self-learning again.

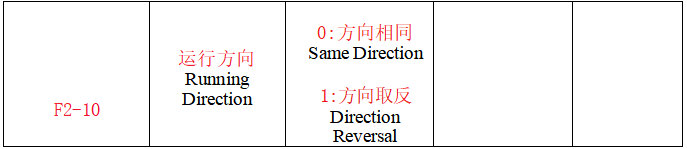

6) 运行方向更改F2-10

Running Direction Adjustment – Parameter F2-10

二、带负载调谐方法(主机已经挂上钢丝绳)

Load Tuning Method (Main Controller with Steel Wire Ropes Attached)

1) 设置好以上参数,断电上电清除故障(小屏幕显示E52, E51故障不影响调谐)

Set the above parameters properly, power off and then power on to clear faults (the display of fault codes E51 and E52 on the small screen will not affect the tuning process).

2) 设置F0-01=l,Fl-ll=l,持续按压检修上行或下行按钮,电机发出"哽"的一声 后,运行十秒左右自动停止。学成后F1-06即是电机角度。至少做三次电机学习, 误差范围应不超过5 ° ;若电机运行方向与按钮方向相反,更改F2-10。

Set F0-01 to 1 and F1-11 to 1. Press and hold the inspection upward or downward button continuously. The motor will emit a "clunk" sound, run for about 10

seconds and then stop automatically. After completion of self-learning, the value ofF1-11 is the motor angle. Perform the motor self-learning at least three times,

with the error range not exceeding 5 °. If the actual running direction of the motor is opposite to the direction indicated by the button, modify the parameter F2-10.

3) 当相序不对时,报E20故障子码3。调换输出线的U,V两相,重新进行主机自学习即可。

If the phase sequence is incorrect, fault code E20 with sub-code 3 will be

reported. Swap the two output lines U and V, and perform the main controller self-learning again.

4) 运行方向更改F2-10

Running Direction Adjustment – Parameter F2-10

异步机主机学习方法

Self-learning Method for Asynchronous Motor

将电梯拨成检修状态。设置编码器的类型及脉冲

Fl-00=2、 Fl-12=1024、 Fl_25=0

Set the elevator to inspection mode. Configure the encoder type and pulse parameters.

Fl-00=2、 Fl-12=1024、 Fl_25=0

1) 设置好以上参数,断电上电清除故障(小屏幕显示E52, E51故障不影响调谐)

Set the above parameters properly, power off and then power on to clear faults (the display of fault codes E51 and E52 on the small screen will not affect the tuning process).

2) 设置F0-01=0,按操作器上的复位键STOP清除故障Fl-ll=l。这时小屏幕上显示TUNE。

按操作器的左下角绿色的键,电机开始静止调谐。电机自学习完成恢复F0-01=l,后可检修试运行。

Set F0-01 to 0, and press the STOP reset button on the operator to clear faults. Then set F1-11 to 1. At this point, "TUNE" will be displayed on the small screen.Press the green RUN button at the bottom left corner of the operator, and the motor will start static tuning. After the motor self-learning is completed, reset F0-01 to 1, and then the elevator can be test-run in inspection mode

3)当相序不对时,报E20故障子码3。调换输出线的U,V两相,重新进行主机自学 习即可。

If the phase sequence is incorrect, fault code E20 with sub-code 3 will be reported. Swap the two output lines U and V, and perform the main controller self-learning again.

4)当报E20故障子码12。调换编码器线的A,B两相,重新进行主机自学习即可。

If fault code E20 with sub-code 12 is reported, swap the two encoder lines A and B, and perform the main controller self-learning again.

5) 运行方向更改 F2-10 Running Direction Adjustment – Parameter F2-10

[Tech-Blog]NICE3000new Main Controller Self-learning Method

[Company news]FUJI Precision Welcomes African Customers for Factory Visit and Strategic Cooperation

[Company news]Elevator Shipment Update | FUJI Precision Factory Ready for Global Delivery

[Hourly News]FUJI Precision Elevator: Completed Test Assembly and Quality Inspection Before Shipment

[Company news]FUJI Precision Elevator Factory | Global Customers Visit China’s Leading Elevator Manufacturer

·NICE3000new Main Controller Self-learning Method

·FUJI Precision Welcomes African Customers for Factory Visit and Strategic Cooperation

·Elevator Shipment Update | FUJI Precision Factory Ready for Global Delivery

·FUJI Precision Elevator: Completed Test Assembly and Quality Inspection Before Shipment

·FUJI Precision Elevator Factory | Global Customers Visit China’s Leading Elevator Manufacturer

·Self-learning method of NICE3000new host

·🚀 FUJI Precision Escalators | Reliable, Safe & Built for High-Traffic Environments

·Why Global Partners Trust FUJI Precision | A Tribute to Our Worldwide Elevator Clients

·FUJI Precision Domestic Escalator Projects | Quality Made in China

Contact Us

×