Modern public buildings such as shopping malls, supermarkets, subway stations, and stations are all equipped with escalators. As a designer, in addition to the concept and basic composition of escalators and relevant specifications, you must also understand the design points and construction process.

Today, we will look at the relevant content of escalators from the following aspects:

1. Construction process of escalators

2. Node structure atlas of escalators

3. Construction points of escalators

1. Construction process of escalators

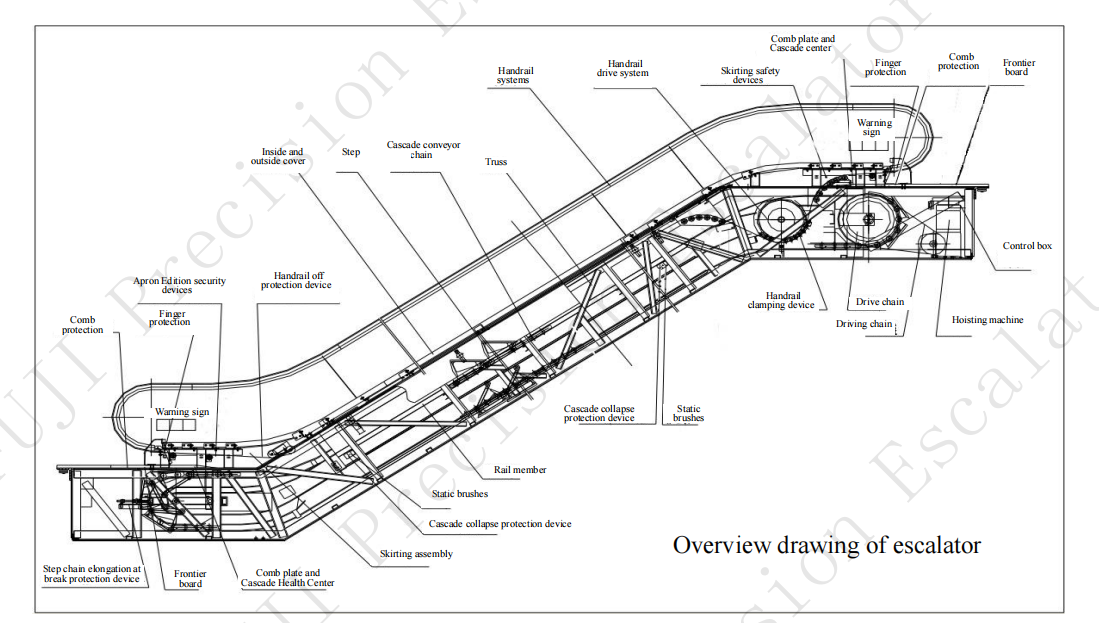

The construction of escalators is relatively complicated, and is usually carried out by manufacturers of professional companies. Let's take the finishing installation process after the main body of the escalator is installed as an example to talk about the relevant construction process. The finishing installation process is mainly a type of process that uses a steel keel frame as a supporting structure and a metal plate as a finishing material.

The construction process is:

Drawing preparation → Install the main body of the escalator → Construction preparation → Measurement and positioning → Fix the steel keel frame → Install the metal decorative panel → Close the end → Run test and self-inspection

1. Drawing preparation

The final construction drawings are formed by civil engineering, escalator manufacturers, and Party A through communication and modification.

2. Install the main body of the escalator

The escalator manufacturer processes, manufactures, installs, debugs and tests the main body of the escalator according to the relevant drawings. Only after the installation is completed and qualified can the next step of installation be carried out.

3. Construction preparation

Confirm that the lighting pipelines and fire sprinklers hidden at the bottom of the escalator have been installed and tested, and confirm that the on-site construction environment conditions meet the construction requirements. Prepare construction materials and tools, build scaffolds, and provide technical briefings to construction personnel.

4. Measurement and positioning

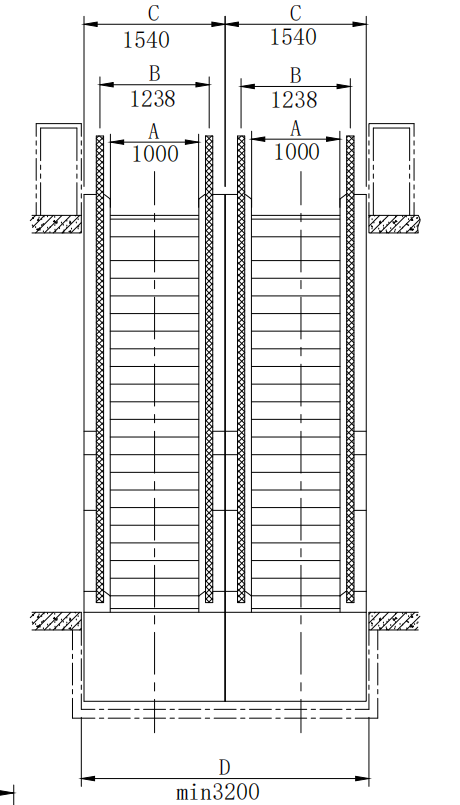

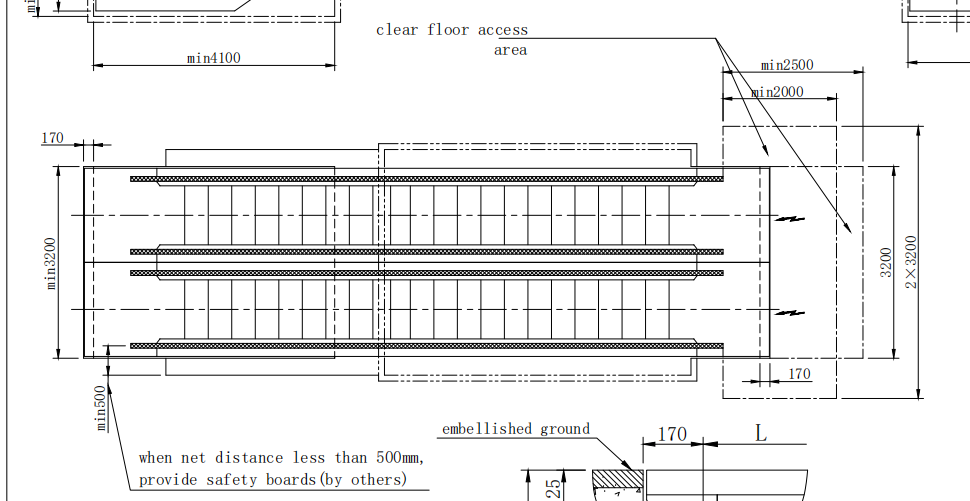

According to the requirements and geometric dimensions of the design drawings, the two sides and the bottom of the escalator are straightened, squared, measured, and marked to determine the size and quantity of the facing metal plates.

5. Fix the steel keel frame

A 12cm thick A-grade bottom plate is used as the base layer, and the horizontal and vertical bars of the steel keel frame are welded and fixed to the main frame of the escalator, and anti-corrosion treatment should be carried out in advance. The installation frame position should be accurate and the connection should be firm. After installation, the center line, surface elevation, etc. should be fully checked.

6. Install metal decorative panels

After installing the bottom LED light strip and sealing the base layer, start installing the escalator metal decorative panels. The installation order starts from the side panels, one side is installed and then the other side, then the bottom corner arc plate is installed, and finally the escalator bottom aluminum plate is installed.

The method of fixing the metal decorative panels is mainly to set the installation holes or install special corner codes during the metal plate processing, and then hang or rivet them on the steel keel frame.

7. Finishing treatment

The finishing of the light trough and the metal plate, the finishing of the ends, the top of the horizontal part, the joint treatment of two different materials, etc., not only affect the decorative effect, but also have a great impact on the use function. Generally, it should be considered clearly in the drawing stage, and the drawing should be drawn comprehensively. After the technical explanation is done, the construction can be carried out according to the drawings.

8. Operation test and self-inspection

After all installations are completed, the escalator is tested again, and the relevant dimensions after the overall completion are reviewed and self-inspected to confirm whether they meet the design drawings and specification requirements.

02. Escalator node structure atlas

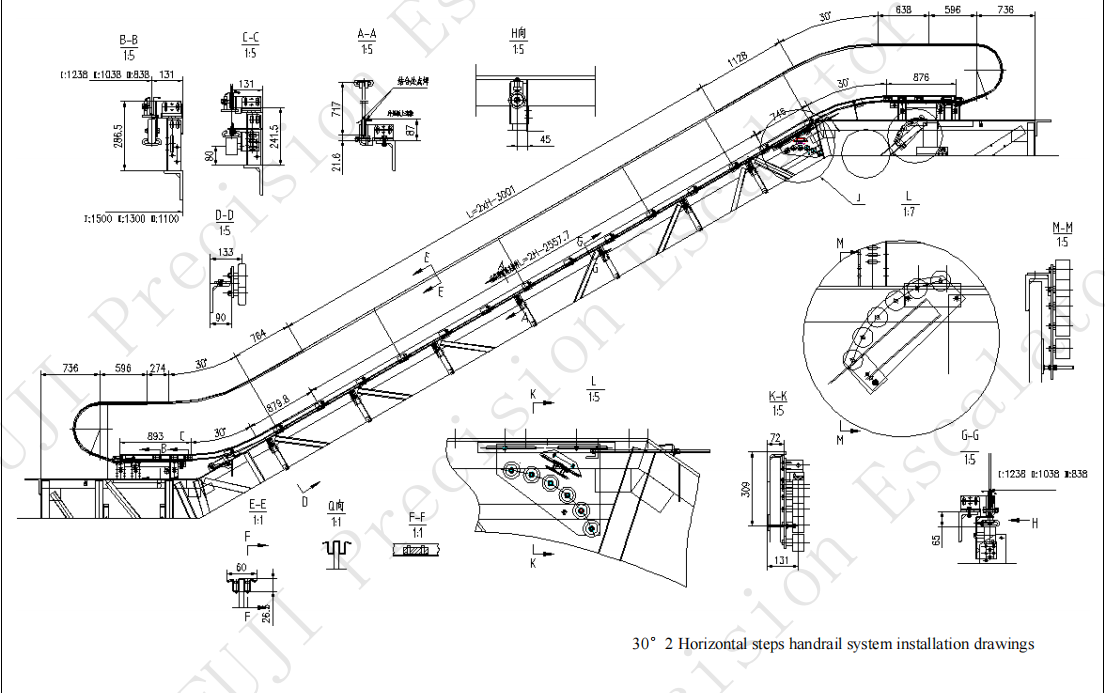

The following is a simple structural diagram to sort out the entire installation and construction process:

FUJI Precision Elevator has a complete installation manual, which can be downloaded from the download page, or you can contact WhatsApp is +86 13306822098

Email :service@precisionfuji.com

https://www.fujijg.com/download/installation_manual/

03. Key points of escalator construction

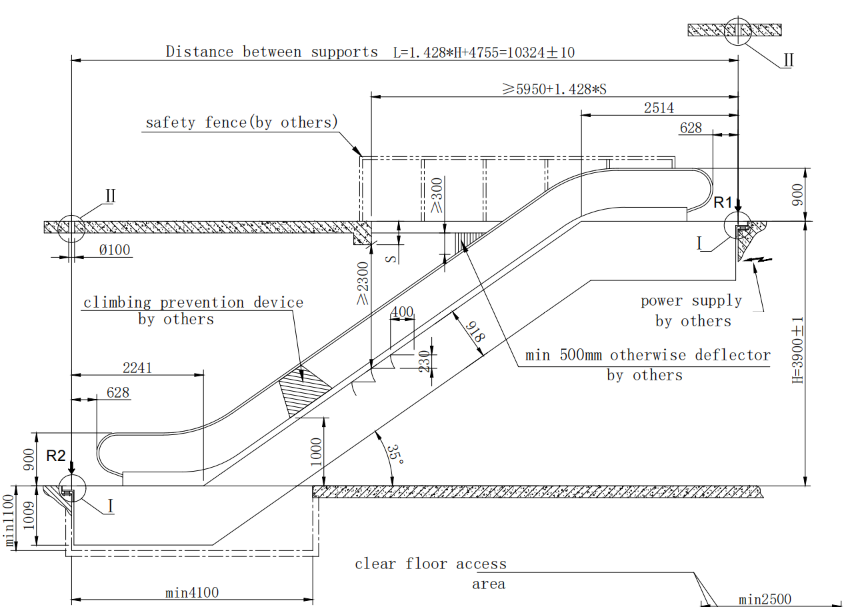

a. Check the civil engineering dimensions of the escalator several times, including measuring the lifting height, span, supporting beams and pit, etc. Pay special attention to the verticality of the upper and lower supporting beams of the escalator and the center line of the escalator.

b. The variety, quality, color, pattern and lines of the metal decorative panels must meet the design requirements and have a product certificate. The specifications and shape of the keel must meet the design requirements, and the fixing of the panel surface and the frame must be firm and not loose.

c. When installing metal decorative panels, the wire should be checked in time to eliminate errors in time. In order to ensure the appearance quality, the bolt position must be accurate.

d. When installing metal decorative panels, the cutting size should be accurate, the edges and corners should be neat and smooth, the overlap size and direction should be correct, and butt jointing is strictly prohibited. The overlap length should meet the design requirements and there should be no penetration.

e. When the metal decorative panels are installed, pay attention to using plastic film to cover and protect the parts that are easily contaminated. Parts that are easily scratched or bumped should be protected by protective plates or safety railings.

f. After the construction is completed, the position relationship between the building floor, the ground surface and the escalator platform should be reviewed. If there is a height difference between the cover plate and the ground material in the escalator area, or the closing relationship is unreasonable, timely adjustments are required.

g. Protective measures (such as padding and shielding) must be taken before construction to protect other completed projects. During the construction process, various water and electricity pipelines and embedded parts must not be damaged due to operation.

i. In addition to meeting the requirements of fire prevention and aesthetics, the external decorative metal panels must also ensure that a force of 250N is applied vertically at any point on the panels to act on an area of 25c㎡ without damage to the external decorative panels or deformation of the gaps.

That’s all about the technology of escalators. If you have any inquiries, you can contact us on our website. FUJI Precision has been engaged in elevator production for more than 20 years and serves all projects. It will provide project guarantees before and after sales, and keep project data for 20 years to ensure the stable operation of the project.

[Tech-Blog]OX-088D Elevator Electronic Safety Gear Instructions

[Tech-Blog]OX-088D Elevator Electronic Safety Gear Instructions

[Company news]Cause analysis and treatment process of 6 typical elevator failure cases

[Company news]FUJI Precision Elevators at Nigeria Exhibition | VR Experience of Our Factory

·OX-088D Elevator Electronic Safety Gear Instructions

·OX-088D Elevator Electronic Safety Gear Instructions

·Cause analysis and treatment process of 6 typical elevator failure cases

·FUJI Precision Elevators at Nigeria Exhibition | VR Experience of Our Factory

·Elevator China | Why FUJI Precision Elevators Are Trusted Worldwide

·FUJI Precision Elevator in Nigeria Villa Project Nears Completion

·What should be inspected during routine elevator inspections? How should it be inspected?

Contact Us

×